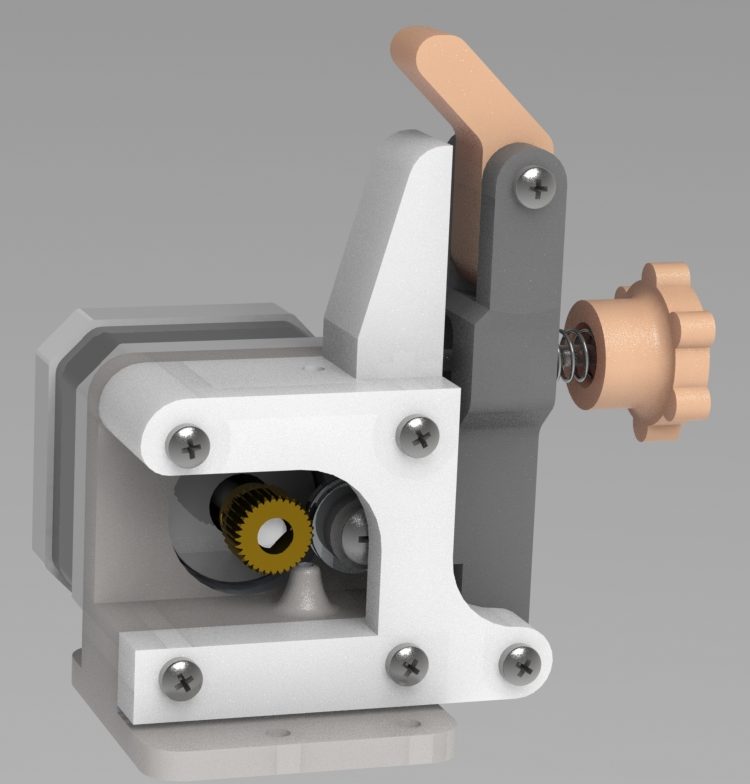

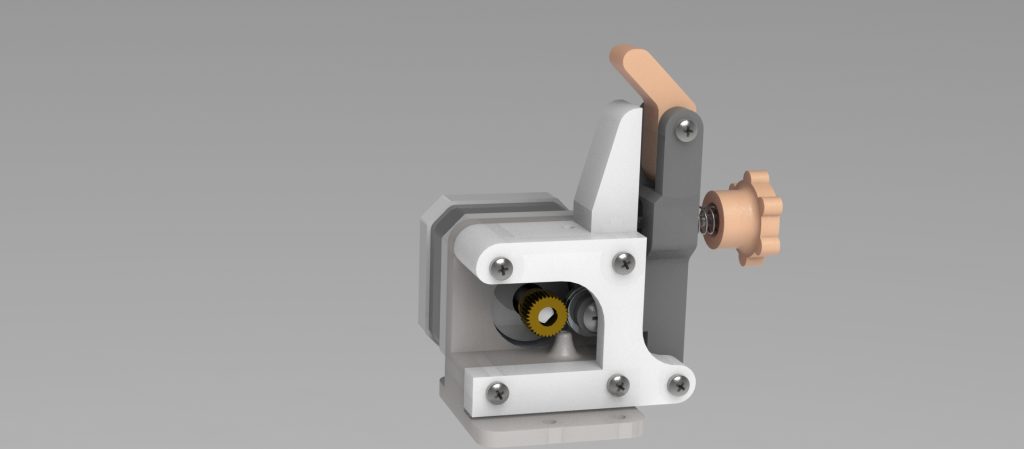

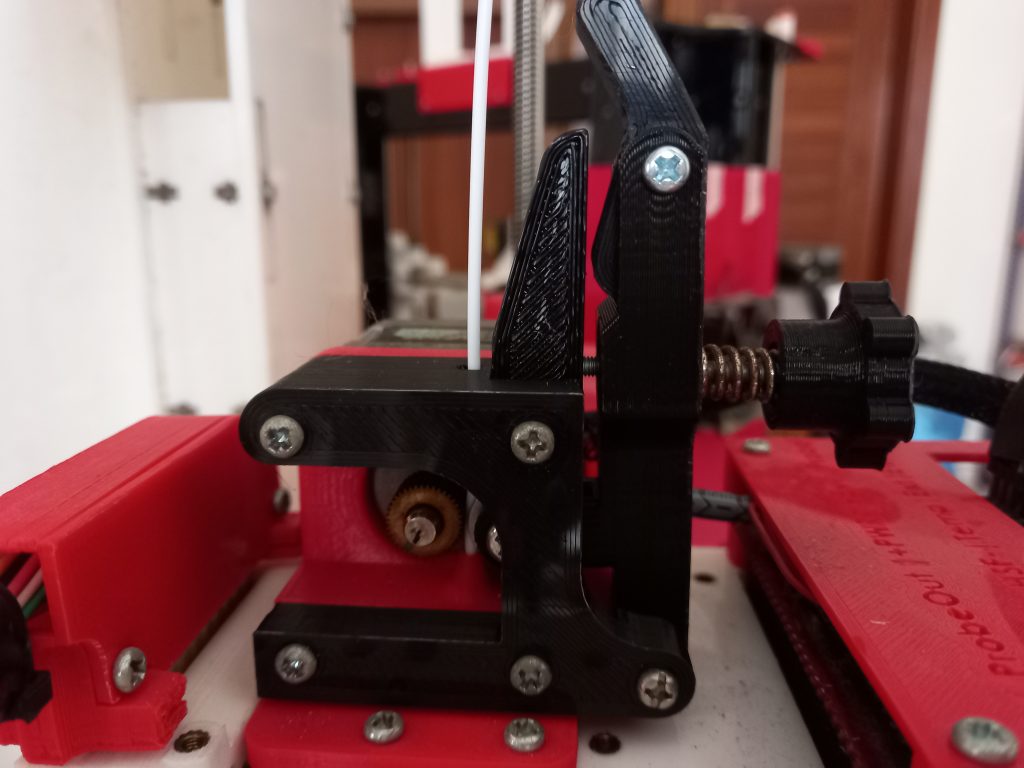

Recently we designed and 3d printed our own extruder for our 3d printer. That design is shown in the image below

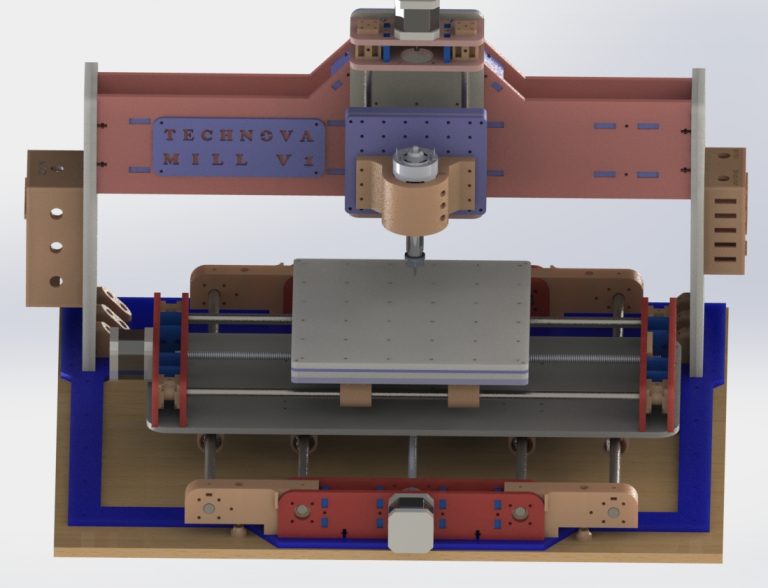

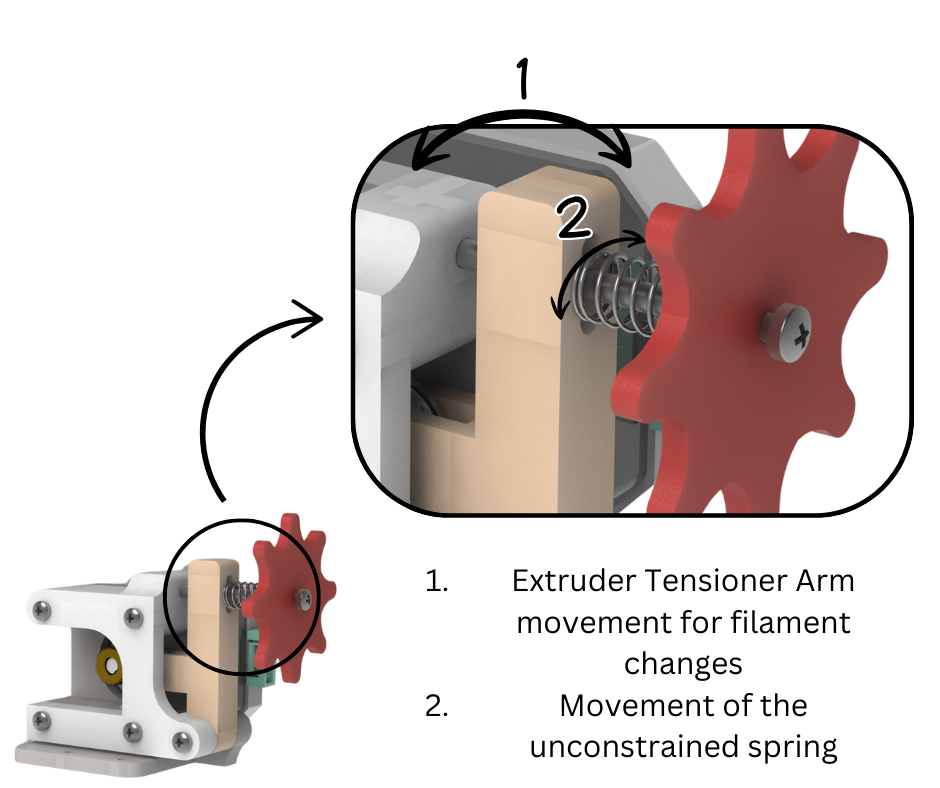

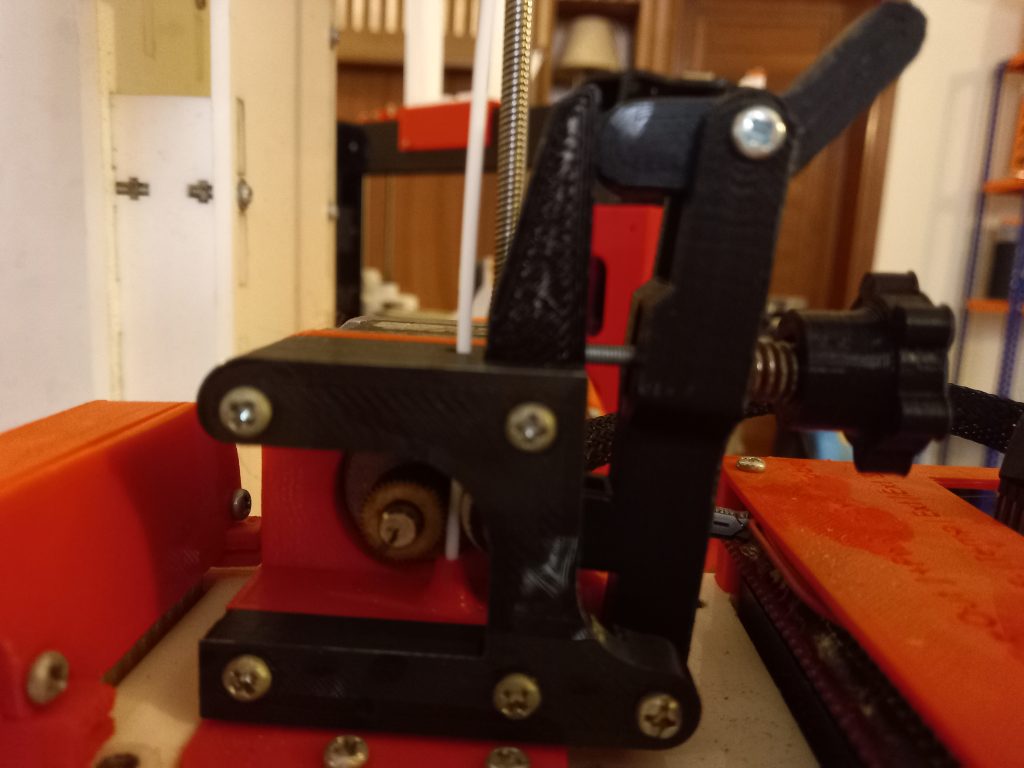

While testing we experienced some issues with this design. These issues can be understood by referencing the image below.

The first issue was that the tensioning spring was constrained only by the bolt going through it. Although the bolt kept the spring in place, it kept the spring in place only loosely. The spring could move slightly side to side as shown in the image below. The spring would eventually get lodged in the slot in the tensioner arm and hinder the movement of the tensioner arm. The second issue was that although there was ample space above the extruder for someone to decompress the tensioner arm to change the filament, the force by the spring required a lot of force needed to decompress the tensioner arm. This usually required two hands. One to hold the extruder and another to pull the tensioner arm. This inconvenience went against the purpose of this design. Therefore we modified this design to create a version 2 which aims at solving these issues. The image below is of our updated design.

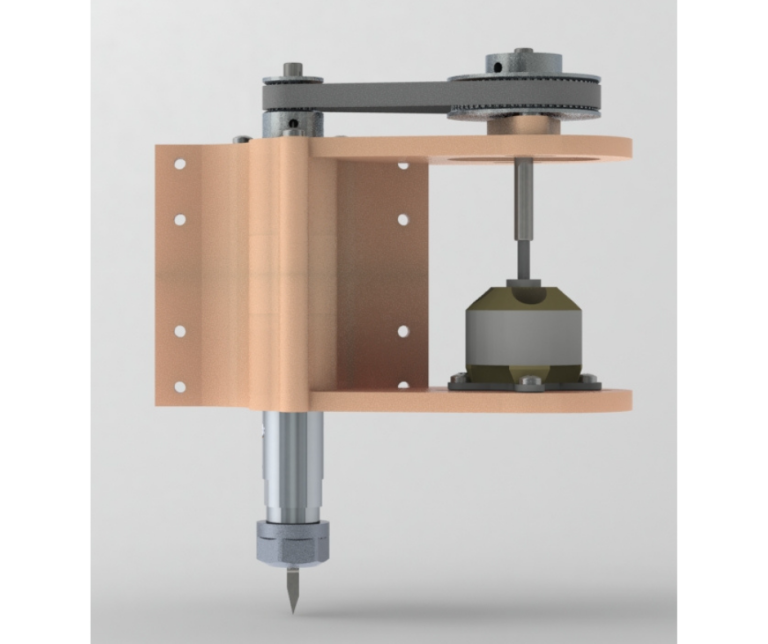

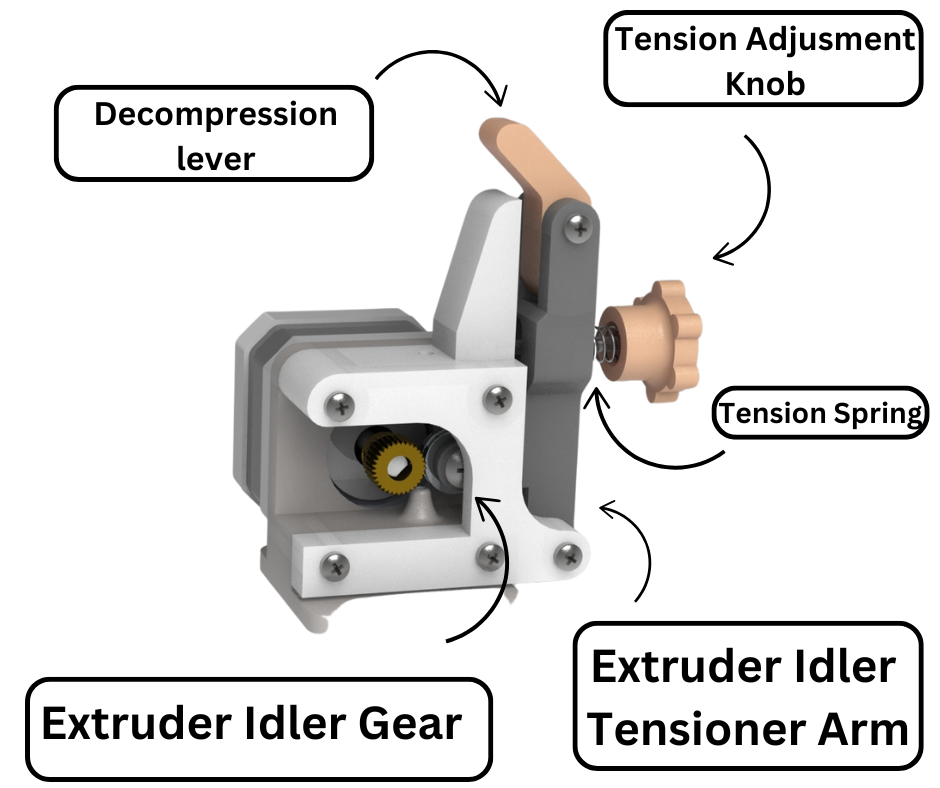

The following image shows some of the features of the new design.

To solve the issue of inconvenience in decompressing the tensioner arm during filament changes, we added a decompression lever. This lever is used to easily decompress the tensioner arm for filament changes.

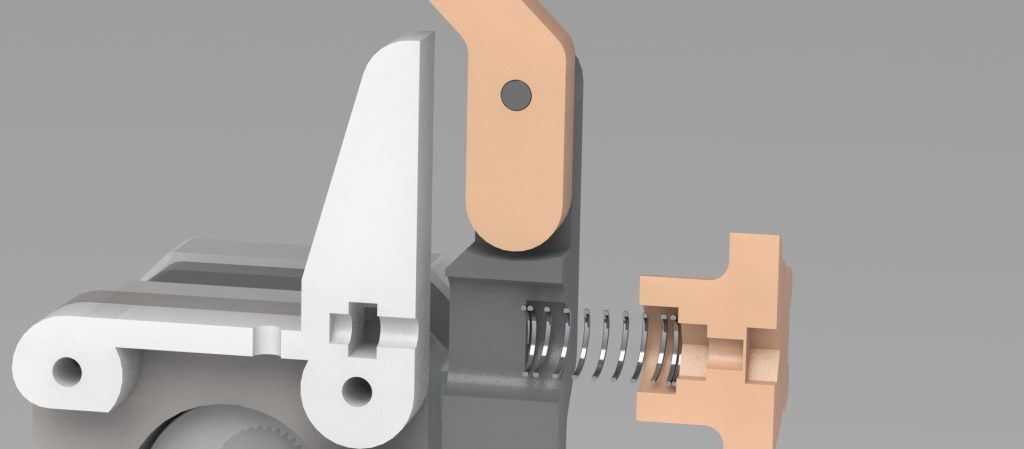

To solve the problem of the unconstrained spring, we added a recessed cavity in both the tensioner arm as well as the adjustment knob. These are shown in the section view image below. The recessed cavity constrains the spring and prevents it from twisting or moving out of place.

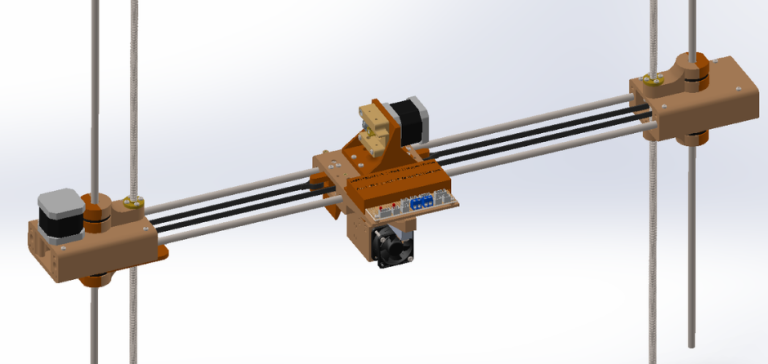

These design changes solve the main issues found the version 1. We 3d printed and assembled version 2 of the extruder and installed it on our 3d printer as can be seen in the images below.

We will be extensively testing this design to verify function and reliability.