It may seem odd that the first blog post on this platform is about a tragedy. But it is a story which inspired the creation of this platform. And the hope is that you can learn from this story as well.

The period of time following the creation of Pakistan in 1947 was filled with difficulty and uncertainty. It was also filled with unbridled enthusiasm, patriotism, hope and will to turn this hard fought piece of land into a country that will stand the test of time. There was a sense of hope and liberty so profound that Muslims well settled in India uprooted their whole lives and came to this country. Amongst them was the late Chaudhry Mohammad Latif.

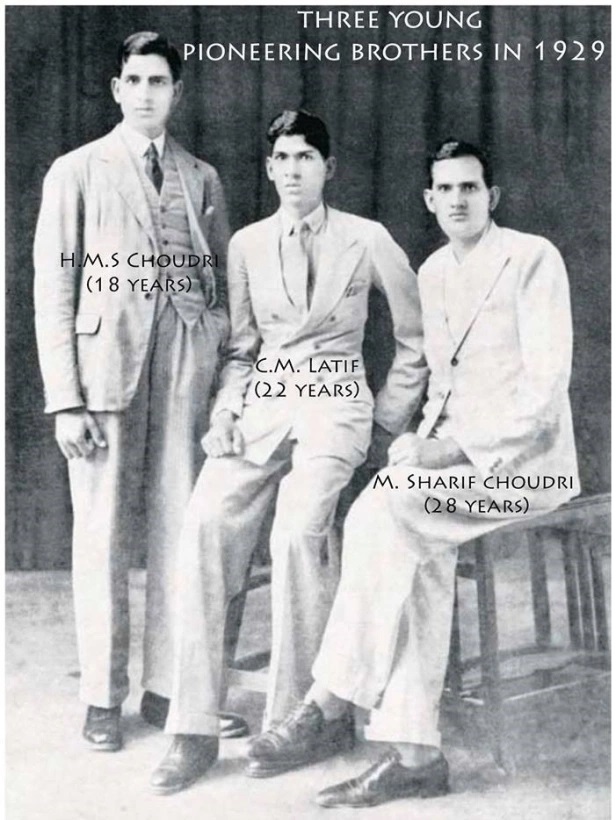

Mr Latif was the founder and chairman of the Batala Engineering Company (BECO). Chaudhry Mohammad Latif started BECO in 1932 in the Indian Subcontinent in an effort to increase Muslim industries to match the Hindu dominance in the retail sector. The name of the company came from place (Batala) where a meeting was held by leading Muslims to address this Hindu Dominance issue. Mr Latif worked almost single-handedly to built this company from the ground up. It started form a modest two room workshop. Mr Latif despite losing much of his business during the migration at Partition, worked tirelessly to turn BECO into one of the finest Engineering Industry in Pakistan to date. So much so that after partition BECO large sums of money to the government to Pakistan to help with the rebuilding process.

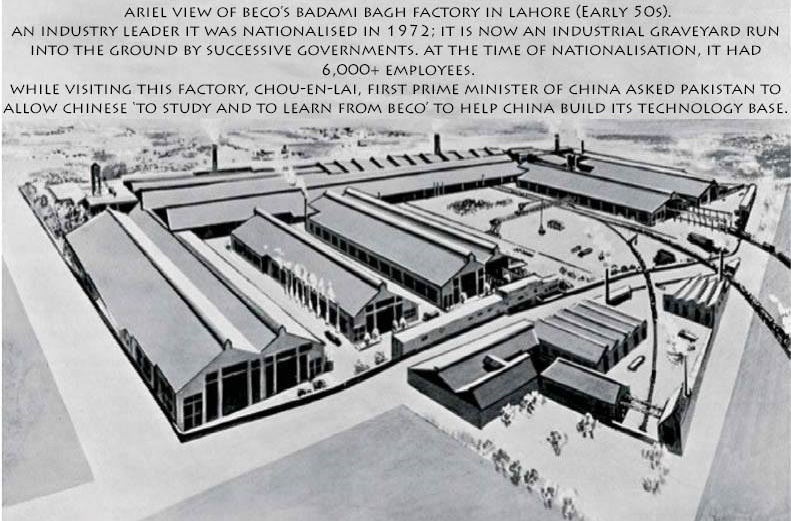

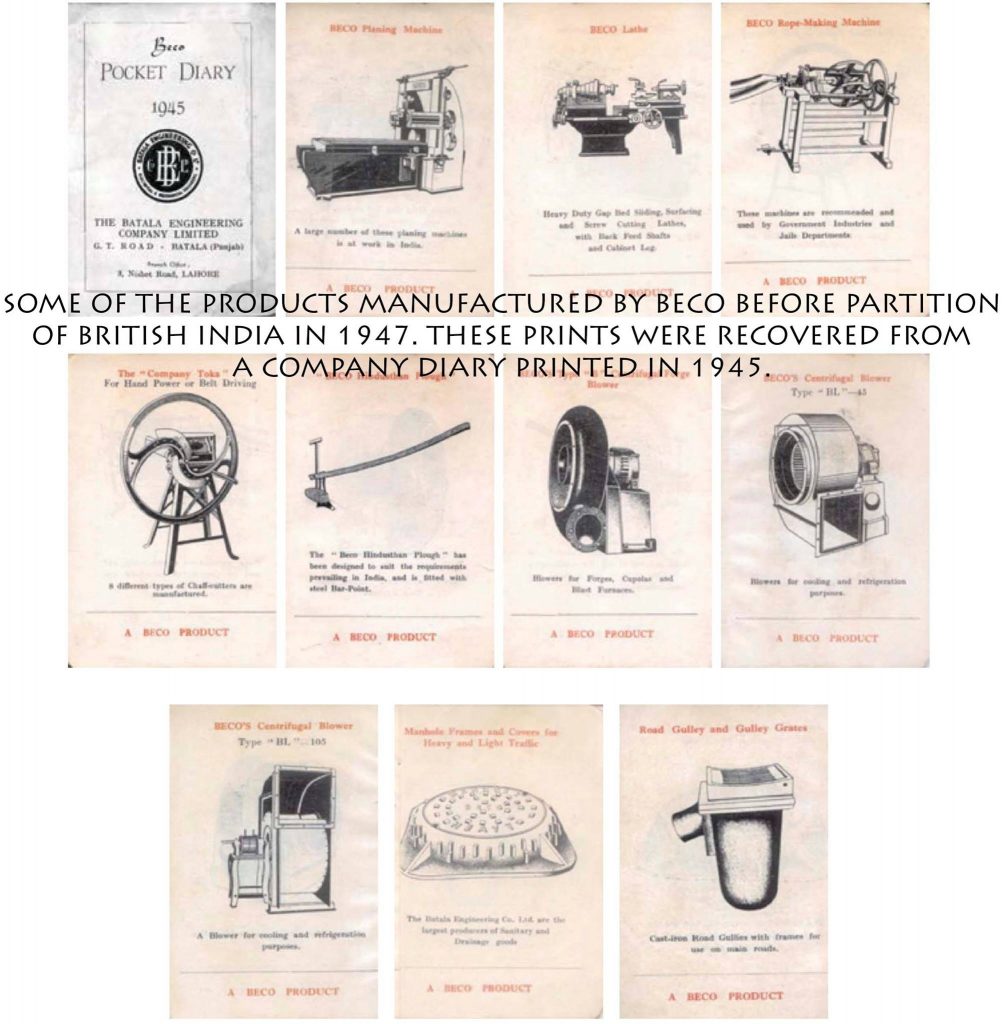

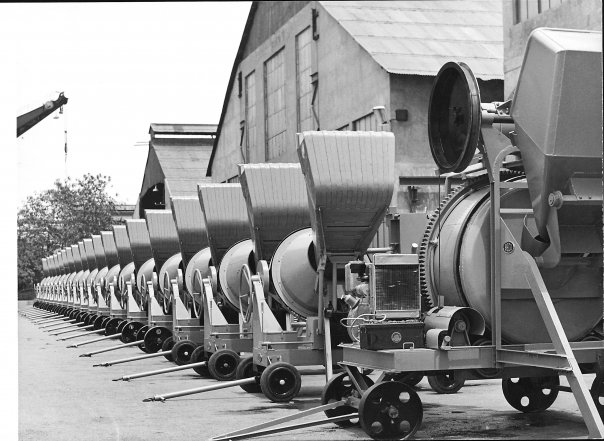

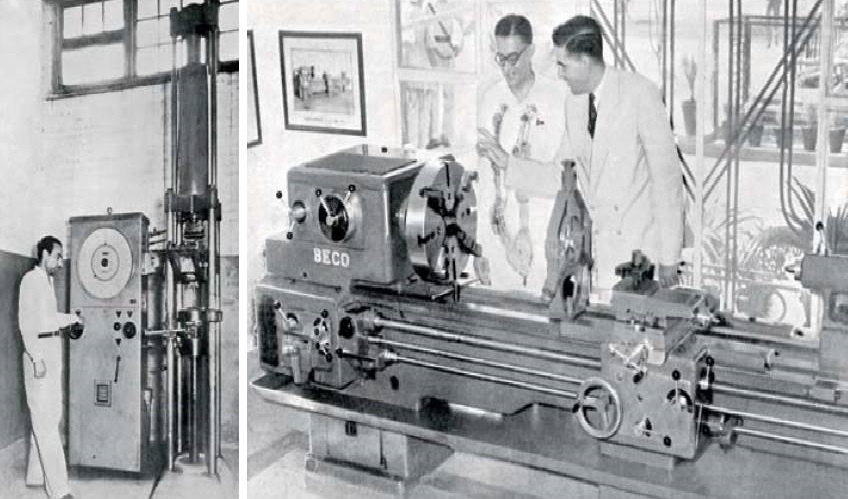

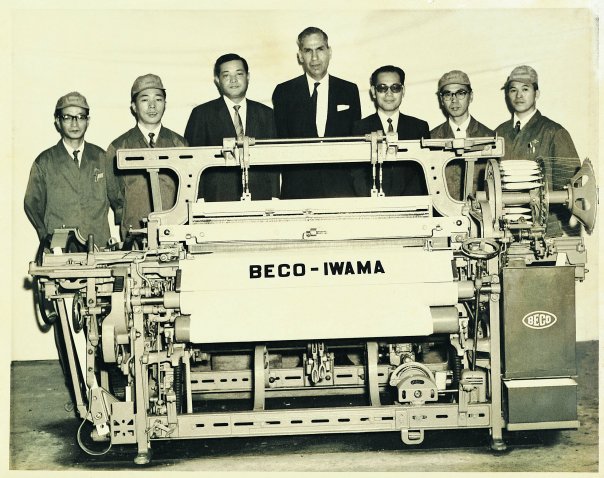

Over the years after Partition Mr Latif grew his Company into one of the biggest Manufacturing Industry at that time. At its peak BECO employed over 6000 workers. BECO manufactured Industrial tools and engines that became examples of excellent Quality, Design and Engineering. BECO was the Pride of Pakistan Manufacturing Industry. Whenever dignitaries from foreign countries came for visits a tour of BECO facilities was always of the agenda. BECO was shown to them as a National Asset. The quality of manufacturing at BECO was so impressive that many of the dignitaries were left in awe. In fact the Chinese prime minister Chou En Lai was so impressed that he requested to send chinese engineers to BECO for training. BECO made Industrial Tools such as Lathes, Air Compressors, Diesel Engines, Pumps, etc. They made custom parts such as barrage door and opening mechanism for use in the irrigation network. BECO also employed international expertise such as Japanese and German Engineers. BECO also partnered with Toyota Corporation to manufacture textile machinery in Pakistan. BECO used parts such as electric motors made in Germany to make very high quality tools such as Lathes, Compressors and Pumps which were then exported all over the world. The quality was so good that countries such as Switzerland that produced their own tools would also import BECO made Industrial equipment. BECO was a crowning jewel of the Pakistan Manufacturing Industry.

At the start of 1972 Zulfikar Bhutto introduced the Nationalization and Economic Reforms that allowed the government to take over 31 key Industrial units including BECO. BECO was renamed Pakistan Engineering Company (PECO). Also among the ventures taken over were nine banks, nine insurance companies, three shipping companies and two petroleum companies altogether belonged to 22 families, who lost most of their assets in the nationalization process. To complete the devastation caused by these reforms, private sector companies were barred from operating in key Industrial fields such as production of Tractors, Automobiles and fertilizers. Private companies had to abandon capital intensive and employment generating projects that were almost complete.

Incapable and corrupt government officials were placed at the helm of companies taken over. Due to mismanagement, inept handling, lack of business acumen and over-staffing most of those units turned into loss-making enterprises, arresting Pakistan’s economic growth and turning a fast developing country into a basket case. By 1998 PECO run up an acknowledged accumulated loss of Rs 761.58 billion. Mr Bhutto single-handedly ruined a national asset and something of which to be proud of as a Pakistani. Had BECO remained in the hands of Mr Latif and his management, it would have given giants such as TaTa and Birla a run for their money.

In 1977 Gen Zia ul Haq offered to return control of BECO to Mr Latif. But Mr Latif was only willing to accept the offer if the other nationalized industries were also returned to their owners. This was not accepted and Mr Latif went to Germany to live the rest of his life there. It was perhaps a good thing that Mr Latif was not personally present to witness the eventual demise of his beloved company for which he had worked and sacrificed so much. Not being able to stem the financial losses being Incurred by PECO, the government did what it does best and abandoned the factory, sold out tons and tons of steel in the building structures and , and now what is left of it is an Industrial graveyard.

The Nationalization of 1972 shows the devastating and far reaching effects of ill planned and hasty decisions taken on the orders of a single man. How could “money making” bureaucrats who had no financial stake in those industrial units run it more efficiently and profitably than the ‘money creating’ industrial tycoons that they replaced? Gradually and as expected those once profitable industrial units were turned into obsolete loss makers. Thereby halting Pakistan’s Industrial growth.

Industries such as BECO and others are the backbone of any developed economy. China which is a manufacturing powerhouse was also once a closed off economy where everything was state owned. Then economic reforms were passed which saw a shift in Chinese manufacturing industry. Private investors and international investors were given incentives to invest and operate in the manufacturing sector in China. This saw an impressive growth in the privately owned industry sector which contributed more than 50 percent of the country’s GDP in 2015 and employed more than 350 million people. In 2018 more than 20 Chinese privately owned companies are ranked amongst the top 500 companies in the world. Pakistan was already in the rapid economic growth period when a single man’s reckless policies not only halted that economic growth but also undid the growth that had taken place.

Now we come to the part of the story where we ask ourselves if we can fix what has taken place. And the answer is ‘YES’. Granted it will take a lot of time to undo the damage that has been caused, but if we care enough about our country then we can start rebuilding. We can start by taking small steps. We need to look at then things that we are importing and ask ourselves if that is something we can make ourselves. We need to develop a mentality of trying to make what we need rather than just buying from someone. All the big engineering companies in the world started from something small and manageable. Then with Research and reinvestment of profits they grew into the giants they are today. We should adapt the same principles. Instead of going for get rich quick schemes we should invest into something that can produce a useful product(s) as well as create employment. Sure it will take time and effort but that can be said for all right things. We should keep Research and Development at the core of any venture that we start. That is how we will continue to grow and not become obsolete.

Keep your efforts going.